Studer S 30-12 cylindrical grinding machine

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Switzerland

Switzerland

Distance between centres 700 mm

Max. Longitudinal travel 700 mm

Grinding wheel:

Diameter 400 mm

Width 50 mm

Bore 1 7 mm

Workpiece weight on centres max. 80 kg

Grinding wheel speeds:

number (steps) 6

from 1500 rpm

up to 400 rpm

Peripheral speed 35 m/s

Angular displacement 0-90 °

Work piece spindle head:

speeds:

stepless

from 30 rpm

up to 675 rpm

rotatable 90 °

Spindle taper 5 MT

Taper in tailstock: 3 MT

Table angular displacement 8 °

Table speed:

stepless

from 0.05 m/min

up to 5.5 m/min

Voltage 50 Hz 3x 380 Volt

External Grinding wheel motor 3 kW

Total power required 13 kVA

Overall dimensions machine:

Length 00 mm

Width 1300 mm

Height 1800 mm

Dimensions of the control:

Length 900 mm

Width 500 mm

Height 1700 mm

Various accessories:

Tailstock with fine adjustement

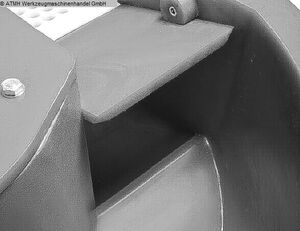

Internal grinding attachment

Spindle speeds 8000 rpm

Redressing device

Laterally pivotable dressing device

Rayon redressing device

Paper filter facility

Set of flanges

Feed SENSITRON

Tailstock with fine adjustement

Grinding wheel guard